[ TUBE LASER CUTTING ]

Customization

and precision

The art of cutting and processing

[ TUBE LASER CUTTING ]

Customization

and precision

The art of cutting and processing

CUTTING AND PROCESSING OF

TUBES AND PROFILES

“Specialization and versatility”

We of Cimolai Galliano are specialized in cutting and processing tubes and profiles.

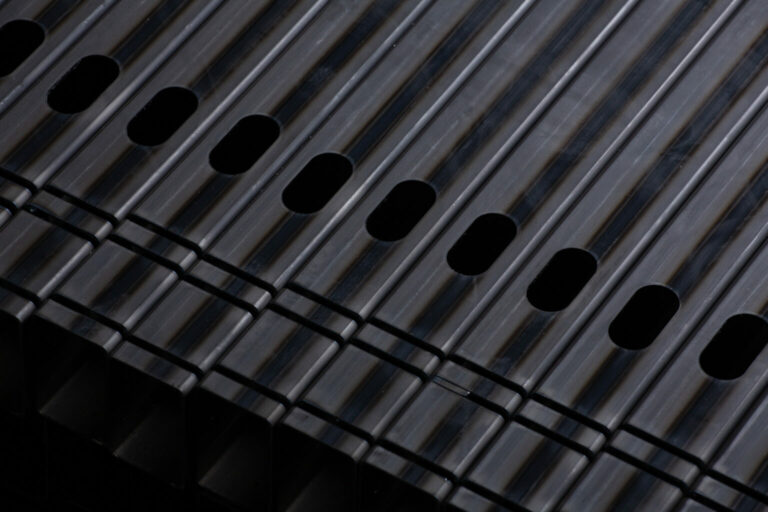

We use 2D and 3D processing systems that allow us to create any shape requested by the customer. Round tubes, quares, rectangles, special sections, open profiles but also H and IPE sections, there are no shape limits within the clamping range between 10 and 240 mm. We are also able to cut by tilting the head, ensuring that the beam hits the surface in a non-orthogonal direction: thus we obtain the so-called 3D laser, which allows us to guarantee any shape.

REVOLUTIONARY TECHNOLOGY

3D LASER CUTTING

“We transform tubes and profiles in unique creations”

3D laser cutting allows us to obtain semi-finished and finished products from tubes and profiles of any shape and size. Thanks to this technology, which allows to guide the head, it’s possible to obtain non perpendicular cuts to the surface, as well as cuts with an angle up to 45 degrees and precise supports for assemblies.

To satisfy any order we equipped ourselves with three Lasertube, of which two are 3D.

The LT5.10, LT7, LT8.20 Lasertubes are all equipped with fiber laser, capable of guaranteeing flexibility and cost-effectiveness.

The LT8.20, thank to its versatility, allows us to be highly performing on both large and small lots.

REAL APPLICATIONS

GALLERY

Immerse yourslef in precision in action where we present our tubes and profiles processes.